Powder Metallurgy Definition Powder Metallurgy is can be defined as the process of preparation and process the powdered iron and nonferrous metals are called as powder metallurgy.

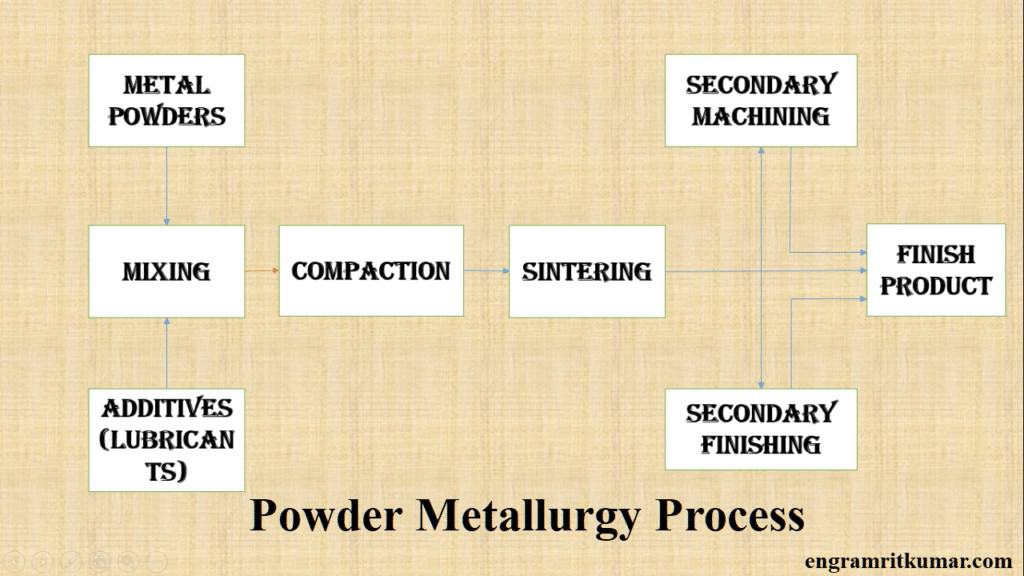

Powder Metallurgy Process These factors make this process most suitable for mass production. It mainly involves four basic steps. Sometimes, this process accomplished with some secondary operations like sizing, coining, infiltration, hot forging, etc.

Powder Metallurgy Process

1. Powder Preparation: This is a first and basic step for producing an object by powder metallurgy process. Any material can convert into powder. There are various processes of producing powder such as atomization, grinding, chemical reaction, electrolysis process, etc.

2. Mixing and Blending As the name implies, this step involves the mixing of two or more material powder to produce a high strength alloy material according to the product requirement. This process ensures even distribution of powder with additives, binders, etc. Sometimes lubricants also added in the blending process to improve flow characteristic of powder.

3. Compacting Compacting means compressed the prepared powder mixture into pre-defined dies. This step ensures to reduce voids and increase the density of the product. The powder is compacted into the mold by the application of pressure to form a product which is called green compact (the product gets by compacting). It involves pressure range from 80 to 1600 MPa. This pressure depends on the properties of metal powder and binders. For soft powder compacting pressure is about 100 – 350 MPa. For steel, iron, etc. the pressure is between 400 – 700 MPa.

4. Sintering The green compact, produced by compressing, is not very strong and can’t be used as a final product. This step involves heating of green compact at an elevated temperature which ensures a permanent strong bond between adjacent particles. This process provides strength to green compact and converts it into a final product. The sintering temperature is generally about 70 to 90 percent of the melting temperature of metal powder.

5. Secondary Operation The sintered object is more porous compared to fully dense material. The density of the product depends upon press capacity, sintering temperature, compressing pressure, etc. Sometimes, the product does not require high density and the sintered product is directly used as a final product. But sometimes, a highly dense product is required (for example manufacturing bearing, etc.) Where a sintered product cannot be used as a finished product. That’s why a secondary operation required to obtain high density and high dimensional accuracy. The most common secondary operation used is sizing, hot forging, coining, infiltration, impregnation, etc.

Powder Metallurgy Advantages · The parts can be produced clean, bright and ready for use. · The composition of the product can be controlled effectively. · Articles of any intricate shape can be manufactured. · Close dimensional tolerance can be achieved. · The machining operation is almost eliminated. · Parts have excellent finish and high dimensional accuracy. · There is the overall economy as material wastage is negligible. · Metals and non-metals can be mixed in any proportion. ·A wide range of properties such as porosity, density, etc. · Can be achieved effectively. · A high production rate can be achieved. · Reduced production time. · Highly skilled labor is not required. · Saving in the material through reduced wastage. · Composition structure and properties can be controlled easily. · A wide range of parts with special electrical and magnetic properties can be produced.

Powder Metallurgy Disadvantages · The high initial cost of metal powder. · The size of the parts produced is limited due to large presses and needed to get required compressing pressure. · The equipment used for the operation is costly. · The impossibility of having a completely dense product. · Pressure up to 100 tonnes capacity is used even for a small product. · The metal powder is expensive and in some case difficult to store. · Some power may present explosion hazards. · Dies used must be of high accuracy and capable of withstanding high pressure and temperature. · Parts produced have poor ductility. · High tooling cost. · The difficulty of sintering low melting powder. · Poor plastic properties. · The necessity of protective atmospheres.

Powder Metallurgy Application · To produce a porous product and Babbitt bearing for automobiles. · To produce oil pump gears for automobiles. · Used for production of cutting tools, wire drawing dies and deep drawing dies. · To produce refractory metal composites, eg: tungsten, molybdenum, tantalum For manufacturing the tungsten wires for filaments in the lamp industry. · Diamond impregnated tools are produced by a mixture of iron powder and diamond dust. · To produced electrical contract material, eg: circuit breakers, relays and resistance welding electrodes. · Parts of cars, aircraft, gas turbine, electric clocks, etc. · Parts of vacuum cleaners, refrigerators parts of guns, sewing machines.

Powder Metallurgy Necessity or Need · Power metallurgy becomes very much in the following cases:

· The difference in the melting temperature of the two elements. · Melting and solidification cause poor quality. · Melting causes loss of identifying the constituents. · Some metals do not form a liquid solution.

Powder Metallurgy Characteristic · Powder metallurgy should be heat resistant. · The size of the powder particles is to pass the powder through the screen (sieves) having a definite number of meshes. · The powder should have good plasticity. · It should have the ability to be cold-pressed. · The powder should have an excellent parking factor. · It should have a good flowability. · The powder should be free from oxides and should have a clean surface. · The ratio of the density of the compact to the apparent density of the powder should vary between 2:1 to 3:1

Source: Learn Mechanical |